Upon arriving at the Club Nautico Reloncavi marina in Puerto Montt the first task was to get the three large cases down the gangway to the floating docks (muelles) and unpack them. Fortunately, everything seemed to have survived the long flight from Seattle.

I was most curious to see how well the Starlink dish would work so in the first few days after arriving and spend my time getting the dish mounted on the arch, running the cable through a new hole I drilled in the deck (with waterproof gasket fitting) and mounting the power supply, router, and small 12 VDC to 120 VAC inverter to the power Starlink components. I connected the inverter to a 30 Amp circuit breaker I had already installed for the Icom HF radio.

The dish itself was mounted to a post welded onto the stern arch next to the solar panels. A Starlink-available pipe mount I brought with me slid perfectly over this post. The mount is normally intended to be held in place by set screws. I don’t rely on set screws to hold anything – they too easily work loose – so I drilled a hole through the mount and the pipe and through-bolted it using a long stainless bolt and locknut I brought with me from home.

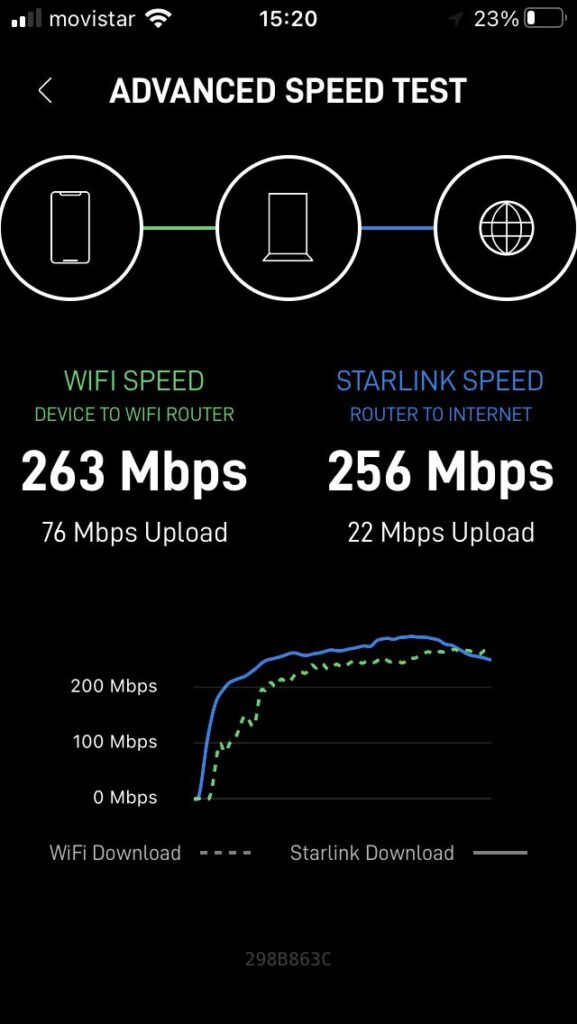

The installation fired right up with download speeds greater than 200 Mbps. I’m very pleased with it. I’ll probably keep my Iridium GO account active for a while as a backup until I see exactly how reliable Starlink will be at sea.

Next on the list was hauling the boat out of the water and putting it on a stand on land (called “on the hard”) so new new anti-fouling paint could be applied. When it came out of the water I was surprised at the fairly poor condition of the paint. The boat had only been in the water for a little over a year. I was even more surprised that the zinc anode on the hub of the prop was completely gone. The zinc anode is meant to be slowly eaten away by the natural electrolysis process that occur when a boat is in salt water. The zinc will get eaten away first before corrosion can start on other metal fittings like the prop or thru-hulls. Normally the zincs would be replaced when they are about 50% gone. On close examination there was no corrosion on prop, and the hull zincs were still in good shape. I replaced the prop zinc with a spare I have but I’ll have to keep a closer eye on it in the future and replace it sooner if needed. It really should not have disappeared completely in a year.

After the old anti-fouling paint on the hull was sanded, 2 coats of anti-fouling paint went on. There were rain showers off and on but the painters got some lucky breaks with dry weather.

After about 6 days out of the water the travel lift came back, picked up the boat, and dropped it in the water where I drove it back to the same place on the dock where it was before. The two travel lifts they have at Reloncavi are small compared to others I’ve seen so I had to disconnect both backstays allowing the lift to drive close enough to the center of the boat to pick it up. I’m never comfortable with the backstays off, especially with some strong winds blowing across the marina, but there is still plenty of tension holding the mast up from the shrouds and forestays. Still, not ideal; I was happy to reconnect the backstays once the boat was back at the dock.

It’s pretty uncomfortable to stay on a boat when it’s on the hard, especially if there’s no place to plug in to get power. A ladder is also needed to get from the ground to the deck – I have a telescoping ladder on board. Instead of staying on the boat, I booked a cabana at Tungulu Cabanas very near the marina up on the hill overlooking the Tenglo Channel – a fantastic view to the south. It was a very pleasant respite that spoiled me, I think. Life on the boat is a downgrade by comparison.

There is still a lot to do. Changing the engine oil and filter come next, and the paper filters in the Racor primary diesel fuel filters. I also need to sort out the many jugs (bidones) of diesel left on board, a few just partially full, five of which were added after I left the boat in Puerto Williams. Some of that fuel looks dirty with small bits of what looks like rust at the bottom. I’m not sure where Mauro got this diesel but I’m inclined to discard some of it. Of course, I have a separate funnel filter I use to put diesel into the deck filler neck, a funnel filter I actually used to carry on my plane. Once I have the diesel sorted out I’ll fill up the main tank and then all the bidones I decide to keep which should give me a total fuel load on departure of about 850 liters. Since the next leg will be almost entirely sailing (hopefully I don’t get becalmed in the Pacific) that fuel load should be much more than needed, certainly more than most people would carry.

After the engine maintenance is completed I’ll turn to the running rigging and sails. I still haven’t raised the mainsail yet so I don’t know its exact condition but expect batten replacement and minor sewing repairs will be needed. The canvas bimini and connector panel to the dodger were also damaged by high winds sailing south in the Atlantic so they also need some patching and sewing work.

I look forward to all the maintenance work being completed so I can start sailing again.